The best way to describe torque is by saying it is the force required to twist off the cap of a beer bottle. And this theory applies to nuts and bolts also, but in reverse. In other words, torque is the force required to keep a nut and bolt tight. U-bolts provide the clamping force required to hold the leaf springs to the axle, and the right torque is very, very, very important.

The weakest part of any spring is where the centerbolt goes through each leaf. And to give that area full strength, we need to make sure there is absolutely no movement taking place between the U-bolts and the only way to eliminate this movement is to be sure the U-bolts are torqued to the manufacturer’s specs.

When torqueing the U-bolts Be sure to do so in a criss-cross fashion.

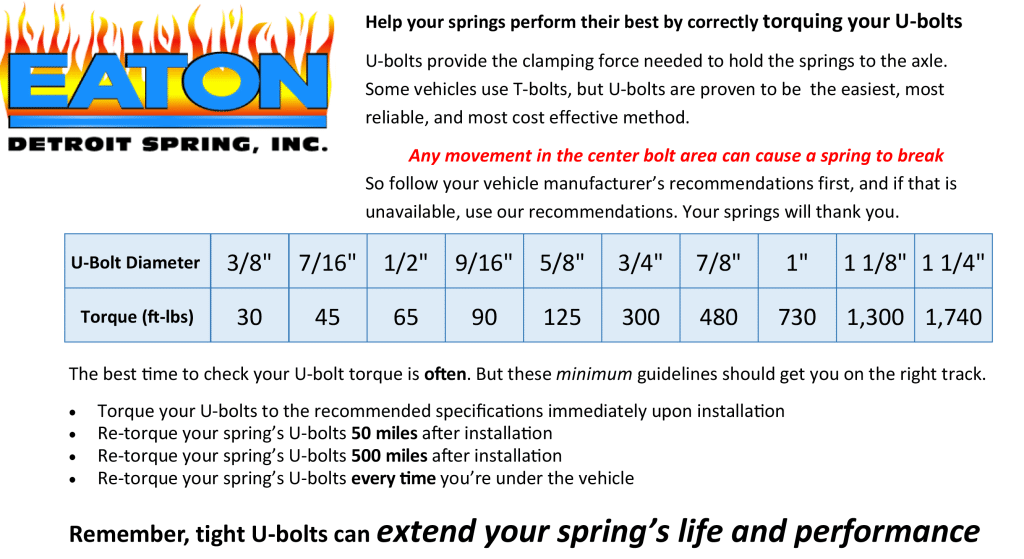

If your springs break between the U-bolts, it means the U-bolts were not tight. If you do not know the manufacturer’s torque specs, use ours. Your springs will thank you.